3LPT Solderable Coatings

3LPT Solderable Coatings

3LPT Solderable Coatings

3LPT Solderable Coatings

These proprietary multi-layer systems are designed specifically for use as solderable coatings for glass, ceramic, and infrared substrates. These films are deposited at less than 200 degrees Celsius which makes them suitable for use on most electronic and infrared optical materials. In addition solderable coating can also be deposited in a frame pattern around a window that is to be soldered onto a metal package. These films have demonstrated excellent adhesion, and have survived destructive solder pot and cryogenic testing.

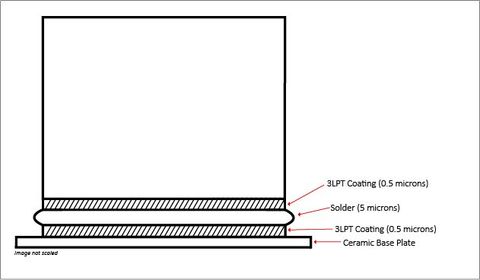

We developed our 3LPT coating as a solution to our customers’ unique problems. One example featured a customer attempting to bond miniature optical components to ceramic using a high-grade epoxy. The epoxy would break down with exposure to radiation, causing the optics to come loose or move out of alignment. Our 3LPT coating was used to replace the joints (Figure 1), resulting in no broken bonds with the ceramic when soldered correctly. The soldered joint often outlasted the actual components.

Another client, using a Ti/Ni/Au coating on Zinc Selenide (ZnSe) windows, experienced approximately a 25% acceptable yield. The solder would often dissolve through the gold exposing the nickel layer to which the solder would not adhere. Sometimes their gold coating completely failed to adhere to the ZnSe. Additionally, the mechanical stresses of thermal expansion would sometimes cause the optical component to fail or the coating to de-laminate. We developed our 3LPT coating to remedy these difficulties. Our proprietary three-layer coating distributes the stresses of thermal expansion, preventing the coating from damaging the optic due to mechanical strain. Platinum is used for the top layer as it doesn’t amalgamate quickly in solder. We have experienced an acceptable yield above 97%. Some of the parts soldered were used in very high-stress applications consisting of rapid altitude and temperature changes with no joint failures and are still in use years later.

Our 3LPT process is superior to any gold solderable coating. Gold coatings need to be very thick, anywhere from 3-10 microns, as the gold dissolves quickly in solder, whereas the 3LPT coating is usually between 0.5 and 1 micron. It is a low-temperature process (below 200º C), making it acceptable for use with more delicate parts and electronics. The exceptional yield and durability mitigate costly repairs to solder joints. 3LPT has undergone extensive stress analysis, including solder pot immersion and cryogenic testing, with little to no effect on the solderable coating and meets MILSPEC-C675C environmental standards. There is no long-term embrittlement with 3LPT as there is when using gold, and many of the parts we coated 20 years ago are still in use today. This coating is suitable for most types of glass, ceramics, and exotic substrates such as Zinc Selenide, Germanium, Zinc Sulfide, Sapphire, and Magnesium Fluoride, to name a few.

Features

- Allows you to solder windows into an optical system

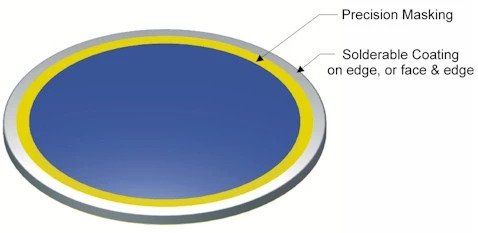

- Available in various shapes and sizes

- Unique Masking Options

- Hermetic Sealing

Applications

- Guidance and Tracking Systems

- Fiber Optics

- Aerospace

- Passive IR Detectors

Specifications

- Name: 3LPT

- Solder immersion compatible

- Tensile strength to exceed glass substrate

- LN2 immersion compatible

Substrates

- Glass (Most Types)

- Germanium

- Silicon

- Zinc Sulfide

- Zinc Selenide

- Sapphire

- Magnesium Fluoride

- Many others