Solderable Case Study 2

Solderable Case Study 2

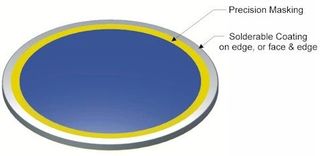

Hermetic Sealing of IR Windows

Customer's Problem

Ordinary solderable coatings were applied to ZnSe infrared windows to hermetically seal them into vacuum dewar detector housings for IR passive imaging systems. The short term yield in assembly was approximately 25% with no leaks. A significant number of parts failed during extended temperature and/or vibration testing. Lead tin solder and organic flux were used in atmosphere.

Failure Modes

Using common coatings such as Ti/Ni/Au, the failure fell into three general categories:

- The solder sometimes dissolved the gold, leaving the nickel to partially oxidize and form a poor joint.

- The entire solderable coating often failed to adhere to the ZnSe

- If the first two hurdles were passed, the final joint often contained enough mechanical stress to rip a layer of the ZnSe off the windows, resulting in catastrophic failure.

Case Study Results

- Typical yields for our 3LPT and EFPT coatings just described are well in excess of 90% usually above 97%.

- The assembled units pass thermal, vibration, immersion and age testing with exceptional reliability.

- This coating system can be used on almost all glass, ceramic, and “exotic” substrates.

- It can be precisely patterned on multiple surfaces in a single operation.

- There is no sign of long term embrittlement of the solder as is sometimes reported with gold coatings.

Coursen Coating Lab's Solution

The customer wanted to continue with lead/tin solder in a non-reducing atmosphere; a coating plan consistent with the process was required. Platinum was chosen since it does not oxidize or dissolve rapidly in solder. A bonding layer of cermet, which adheres very well to most glass and ceramic materials, was used below the platinum. This coating adhered well and soldered well, but ripped out a layer of the substrate after thermal cycling. A third layer of expansion matching material was then included in the system to reduce stress in the joint.

Applications

- Guidance and Tracking Systems

- Passive IR Detectors

- Fiber Optics

- Aerospace