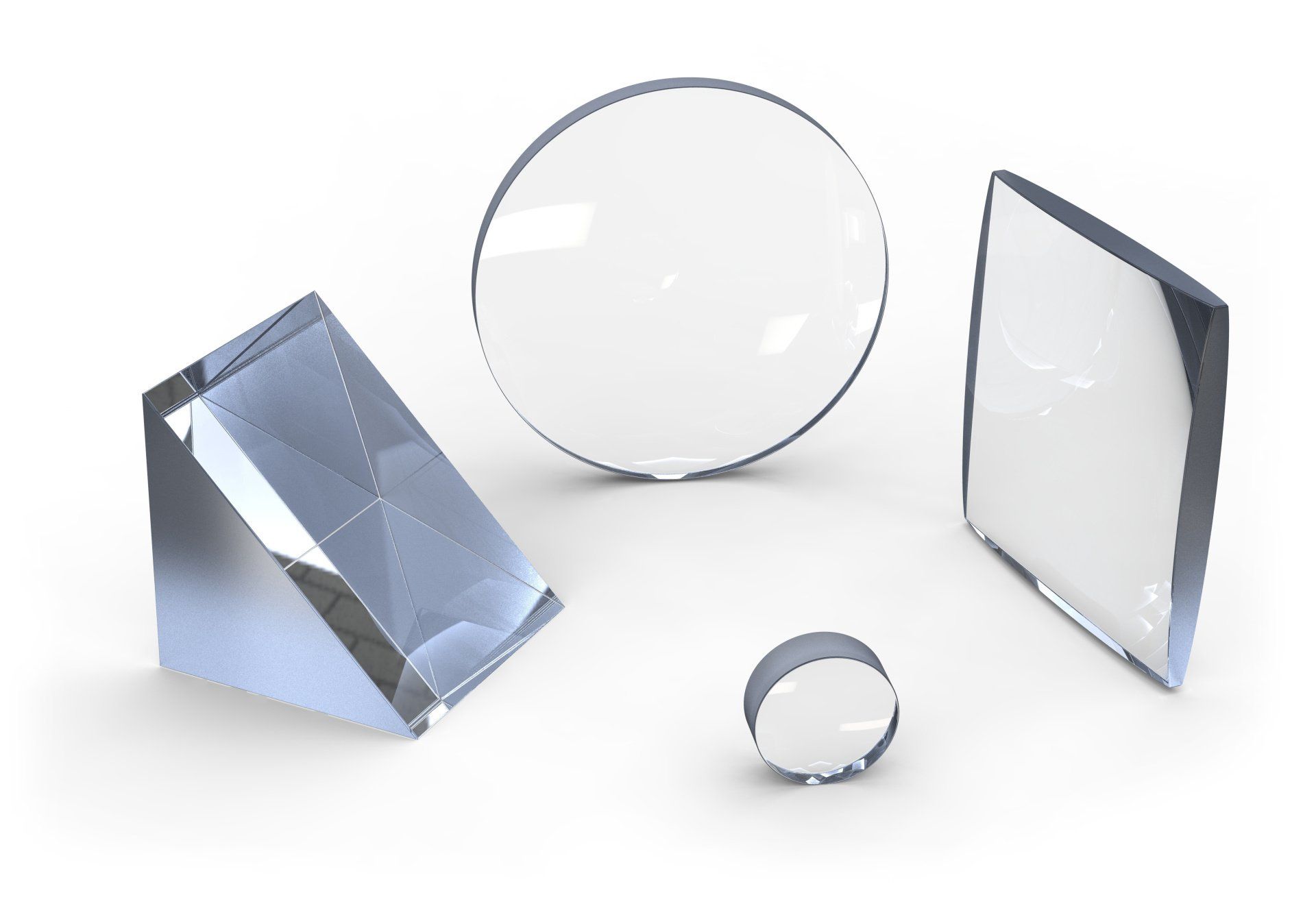

Optical Substrates

Optical Substrates

Perform the basic functions of focusing, bending, or controlling light. Substrates and components are made of glass, metals, ceramics, or plastic. They almost always require a coating. Applications are very broad and numerous and include all of the applications listed in this website.

Sapphire (AI2O3)

Button

Schott BOROFLOAT ®

33 – Borosilicate Glass

Schott BOROFLOAT ®

33 – Borosilicate Glass

Borosilicate glass, previously known as Pyrex, is desirable due to its low Co-efficient of Thermal Expansion (CTE) particularly in environments where expansion is not needed or wanted. It exhibits exceptionally high transparency, high chemical durability, and excellent mechanical strength. It offers reliable and consistent quality while helping to keep your costs down.

Request A Quote

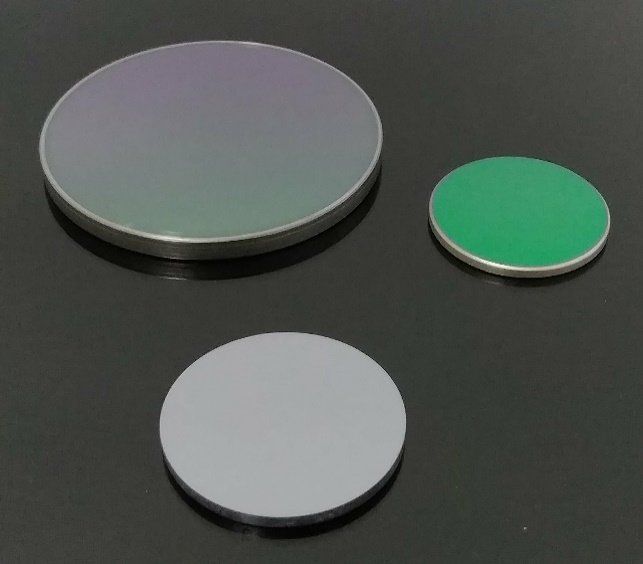

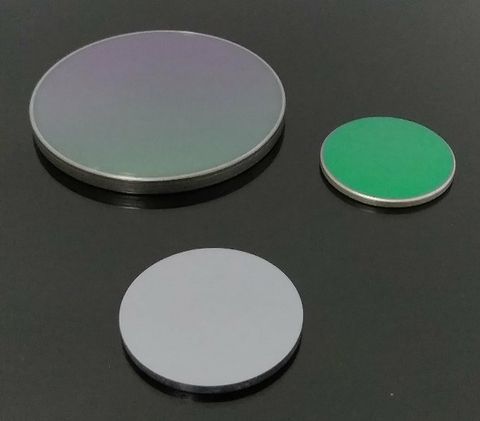

Optical Filter Glass

Optical Filter Glass

We are proud to offer a variety of filter glass from Schott and other manufacturers. Filter glass is known for its selective absorption in the visible wavelength range. Different colored Filter glass will provide different spectral results. This glass can also be coated with a thin film to further refine its characteristics.

Sapphire

Sapphire

Sapphire is an excellent substrate due to its extreme surface hardness and chemical resistance. It is possible to make sapphire windows both thinner and stronger than other types of optically clear substrate. Sapphire is useful in a transmission range from 0.2 – 5.5μm. Basal plane, or C-Plane, cut sapphire is the most suitable for optical substrates.

Schott Specifications

| Attribute | Commercial Quality | Precision Quality | Ultra-Precision Quality |

|---|---|---|---|

| Size (round and square) | Ø from 10 to 300 mm | □ from 10 to 210 mm | ||

| Size tolerance¹ | ± 0.2 mm | ± 0.10 mm | ± 0.05 mm |

| Thickness¹ | From 1 to 40 mm | ||

| Thickness Tolerance¹ | ± 0.2 mm | ± 0.10 mm | |

| Parallelism¹ | < 5 arc minutes | < 1 arc minute | < 30 arc seconds |

| Surface accuracy (PV)¹ | 5 λ (546 nm) | λ/2 (546 nm) | λ/10 (546 nm) |

| Surface quality (scratch & dig) | According to MIL 80 - 50 | According to MIL 40 - 20 | According to MIL 20 – 10 |

| Surface roughness (Rg) | < 10 nm | < 3 nm | < 1 nm |

| AR coating | Custom-designed | ||

| Order quantity | Depending on customer specifications. Please contact us. |

Infrared Substrates

Infrared Substrates

Infrared (IR) products are used in a wide variety of applications ranging from thermal imaging to IR Spectroscopy. A wide selection of materials is available for infrared applications for wavelength ranges 0.750 - 3µm (near-infrared, NIR), 3 -30µm (mid-wave infrared, MWIR), and 30 – 1000µm (far-infrared, FIR). The most used materials are Germanium (Ge), Zinc Selenide (ZnSe), Sapphire (Al2O3), and UV Fused Silica (UVFS). There are many more substrates which are suitable for infrared applications and we would be happy to assist you in determining which is optimal for your needs.

Glass Substrates & Components

Glass Substrates & Components

Perform the basic functions of focusing, bending, or controlling light. Substrates and components are made of glass, metals, ceramics, or plastic. They almost always require a coating. Applications are very broad and numerous and include all of the applications listed in this website.

Other Substrates

Other Substrates

In addition to the substrates already listed, Coursen Coating Labs offers many others. For a complete listing of the Schott products we offer, click this link. If you need a non-standard size, we have options for resizing the substrate to fit your needs as well. Please contact us with your requirements so we may help you determine the best option for you.